Tooling Solutions

Home > Tooling development

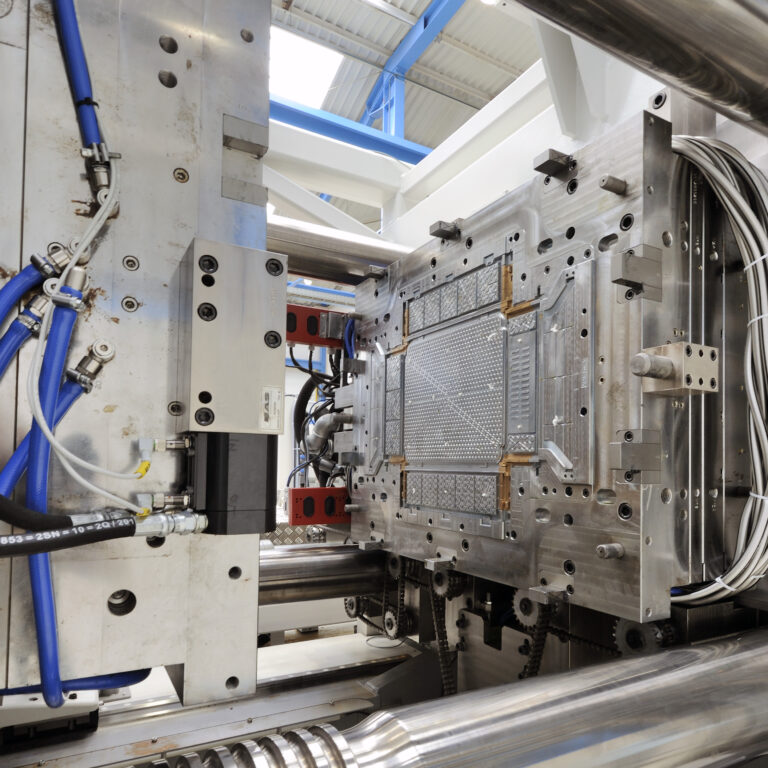

- High cavitations molds

- Appropriate hot runner design and selection.

- Low cycle molds (5000 shots)

- High cycle molds ( over 10 million )

- Multi-Material molding (2k) and insert molding

Tooling is not a one-size-fits-all operation; questions of cost, purpose, and timeline need to be addressed when you’re beginning to work with a tooling partner. Many people don’t realize that there are three distinct classification types of tooling: prototype tooling, bridge

tooling, and production tooling

- Prototype Tooling

- Bridge Tooling

- Production Tooling

Prototype tooling is a method used in rapid prototyping to create different parts for a prototype with the help of low-cost injection moulds. This method, also known as soft tooling or rapid tooling, allows the creation of several parts as fast as possible.

Bridge Manufacturing uses 3D printing to produce low-volume runs of a part before mass production with traditional methods. This process is a useful step before bringing a product to market. It enables a smooth transition from rapid prototyping to mass production.

Production tooling refers to plastic injection moulding tools and dies that are built to withstand the rigorous demands of mass production while maintaining tight dimensional tolerances on every finished part.