Plastic Injection Moulding

Home > Plastic Injection Moulding

Injection moulding uses a special-purpose machine that has three parts: the injection unit, the mould and the clamp. Injection moulding is a method to obtain moulded products by injecting plastic materials molten by heat into a mould, and then cooling and solidifying them.

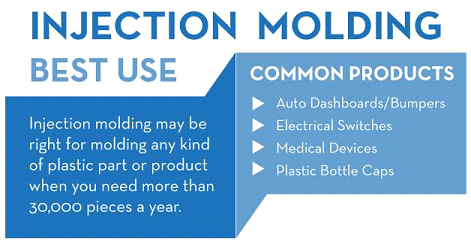

This is a common method to produce a high volume of plastic parts like car parts or even parts for surgical applications. Products can also be made with increased flexibility to suit the needs of designers or engineers.When it comes to the pricing the moulds can be very expensive because they need to be steel or aluminium for higher strength and durability. Luckily, as with most methods, the cost per unit drops drastically depending on your production volume

It is also worth noting that tooling can take up to 16 weeks and production up to 4 weeks..

Our Capabilities of 2 Moulding Machine 180 ton and 120 ton helps us in our trial with in-house Tooling Solutions and moulding Support for our customers. Types of moulding possibility